333 Ridge Cap Forming Machine för stegplattor

$14500≥1Set/Sets

| Betalning Typ: | L/C,T/T,D/P |

| Incoterm: | FOB |

| Min. Beställ: | 1 Set/Sets |

| Transportfordon: | Ocean,Land |

| Hamn: | Tianjin New Port |

$14500≥1Set/Sets

| Betalning Typ: | L/C,T/T,D/P |

| Incoterm: | FOB |

| Min. Beställ: | 1 Set/Sets |

| Transportfordon: | Ocean,Land |

| Hamn: | Tianjin New Port |

Modell nr: XF 333 Ridge Cap Forming Machine

Märke: Xf

Tillämplig Industri: Byggnadsmaterialbutiker

Utan Garanti: Videoteknisk support, Online -stöd, Reservdelar, Fältunderhåll och reparationstjänst

Var Man Kan Tillhandahålla Lokala Tjänster (där Länder Finns Utländska Serviceuttag): Ingen

Showroom -plats (i Vilka Länder Finns Exemplar Utomlands): Ingen

Gammal Och Ny: Ny

Maskintyp: Kakelformningsmaskin

Kakeltyp: Färgad

Använda Sig Av: Tak

Produktivitet: 5 m/min

Härstamning: Kina

Garantiperiod: 1 år

Kärnförsäljningsplats: Lätt att använda

Rullande Thinckness: 0,3-0,8 mm

Utfodringsbredd: Övrig

Mekanisk Testrapport: Försedd

Videovårdsinspektion: Försedd

Marknadsföringstyp: Vanlig produkt

Kärnkomponentgarantiperiod: 1 år

Kärnkomponenter: Plc

Customized: Customized

Usage: Roof

Material Of Rollers: 45# Steel

Tile Type: Colored Steel

Transmission Method: Hydraulic Pressure

Suitable To Process: Color Steel Plate

Use: Roofing Tile

The Service Life Of The: 15 Years

Machine Name: Ridge Cap Roll Forming Machine

| Sælgende enheder | : | Set/Sets |

| Pakketype | : | Vi har professionella tekniker för att ladda garanterat varorbelastningen i containern utan skador. |

| Billedeksempel | : |

|

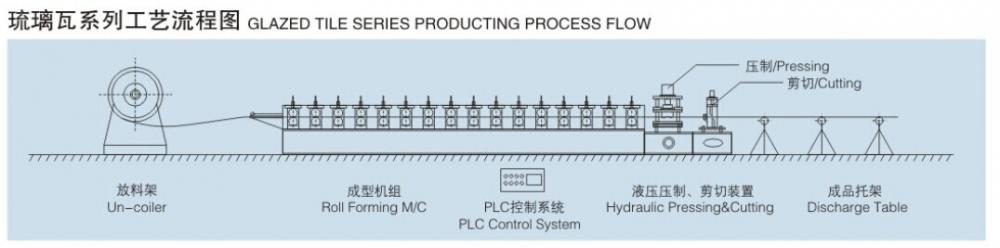

Glazed Tile Ridge Cap Roll Forming Machine for Step Tile Roof. The feeding material for Roof Ridge Cap Roll Forming Machine is 333mm, 0.3-0.6mm. The station of Ridge Cap Machine is 15 Rows. Speed of Ridge Cap Roll Forming Machine will up to 4m/min. If you need other profile ridge cap forming machine, pls contact us. We could recommend one for you.

Quick Detail

1.Suitable to process: Color steel plate

2.Width of the plate: 333 mm

3.Rollers: 15rows

4.Dimensions: 8.6*1.45*1.51m

5.Power: 5.5+5.5kw

6.Thickness of the plate:0.3-0.6mm

7.Diameter of the roller:Φ66mm

8.Weight: About 4T

9.Voltage: 380V 50Hz 3phases

10.Hydraulic: 40#

11.Processing precision: Within 1.00mm

12.Control system: PLC control

Industrial Process And Component Specification

Manual Uncoiler

Usage: It is used to support the steel coil and uncoil it in a turnable way. The steel coil is uncoiled by hand.

Loading capacity: 3T,Inner diameter: 500-508mm

Main Roll Forming Machine

Material of rollers: 45# steel, roller surfaces polishing, hard plating.

The polished surface and the heat treatment towards the molds also can keep the molding.

Plate surface smooth and not easy to be marked when it is being stamped

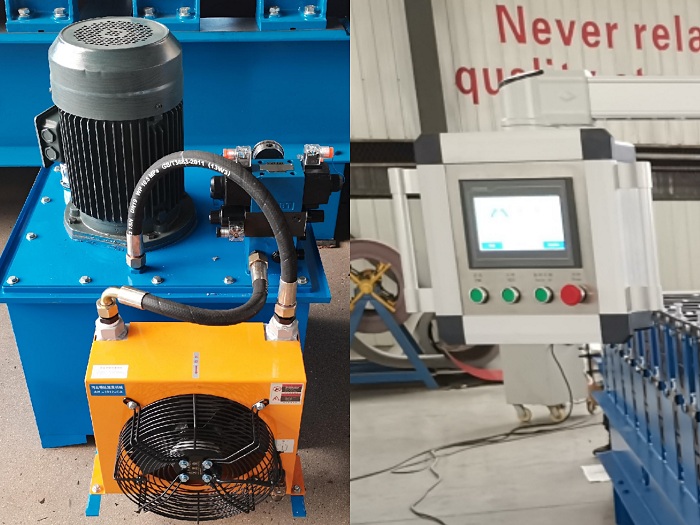

Hydraulic System and Computer Control Cabinet

Power:4KW, Hydraulic oil:40#.Hydraulic oil into the hydraulic oil tank, the pump drives the cutter machine to begin the cutting job.

The target piece`s length is adjustable and digit of it can be adjusted.

Computed mode has two modes: automatic and manual one. The system is easy to operate and use. Plc: Delta Touch Screen

Press Form

Material of blades: Cr12,quenching treatment

Shearing Mechanism

It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products.

Material of blades: Cr12, quenching treatment.

Förpackning och frakt

1 . We have professional technicians for loading

Guaranteed the goods load into container without any damage.

2. Transportation : Machines need one 40 feet container to hold

Våra tjänster

1. Warranty

One year,and we will provide technical support for wholelife of the equipment.

2. Installation And Charge

Purchaser pays all charges during period of install to overseas,

(include charges of food,lodging and round trip air tickets ,etc.)

Moreover,pay subsidy 100USD/day until Installation finished.

If problems happened out of warranty and need debugging overseas

Customer should pay for all the charges (including food,lodging and round trip air tickets etc.)

Moreover pay 100USD/day till install finished

Botou Xianfa Roll Forming Machine Factory

Company Certification

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.